Getting The Safety Network To Work

Wiki Article

10 Easy Facts About Safety Network Explained

Table of ContentsRumored Buzz on Safety NetworkWhat Does Safety Network Do?All About Safety NetworkHow Safety Network can Save You Time, Stress, and Money.The Facts About Safety Network RevealedEverything about Safety Network

Web traffic signal controllers alternative solution between contradictory traffic motions. This requires task of environment-friendly time to one motion, then to one more. If left turns have different controls, and at complicated intersections, there might be greater than 2 conflicting motions. The size of time required to finish one round of service for all contrasting motions is called the cycle size, and also the allowance of the cycle size between the contrasting traffic movements is called the split.This is called squadron development as well as is accomplished by coordinating the operation of nearby signals (https://zenwriting.net/s4fetynetw0rk/h2-style-clear-both-id-content-section-0-the-best-strategy-to-use-for). Signal sychronisation is most frequently attained by operating adjacent signals at the very same cycle length, with a pre-determined countered between the start of the cycle at one junction as well as the start of the cycle at the next.

The cycle size, split, and also counter might need to alter during the day as traffic volumes change. Traffic control services. Controllers, consequently, permit the user to establish several collections of these standard control timing criteria. Each such collection is referred to as a timing plan or timing pattern, as well as one timing plan or timing pattern functions at any type of offered time.

What Does Safety Network Do?

Traffic signal controllers offered today can be categorized as interval controllers (additionally called pretimed) or stage controllers (additionally called actuated). The previous enable the user to divide the cycle right into any type of variety of periods, with the period of each period being established by the individual. The user then defines which result circuits are activated throughout which intervals.The cycle length equates to the sum of the interval periods, and also all intervals are timed sequentially. The customer can likewise specify a start-of-cycle offset for signal sychronisation. The interval periods, outcome definitions, cycle size, as well as offset can all be differed from one pattern to an additional, and also as a result can be varied throughout the day.

If the signal is coordinated, the customer also specifies a split time for every stage, as well as a start-of-cycle countered. The user appoints a stage to a set of suitable vehicle as well as pedestrian movements. If worked with, the split times for all stages in a ring should sum to the cycle size.

Little Known Facts About Safety Network.

Stages assigned to the exact same ring time sequentially, yet rings time concurrently. If the controller is utilizing 2 rings, 2 phases can be timing at the same time as well as separately. Stage controllers make use of barriers or phase concurrency teams to specify problems between stages in various tings. Within a concurrency team (in between two obstacles) the phases in different rings can time separately, however all rings should go across the barrier (transfer to a different stage concurrency group) simultaneously.From one pattern to the following, the individual may vary the cycle size, offset, split, and also phase series. Phase control is specifically well matched to activated control of regular crossways, especially those with secured left turn motions. Two actuated left turn stages on the exact same street can time individually, with claim the westbound turn phase getting much less time than the eastbound in one cycle, as well as the contrary taking place in the next cycle.

Each phase in a stage controller can be operated either pretimed (fixed time) or actuated. The National Electric Manufacturers Association (NEMA) TS 2 standard defines minimum practical requirements for both interval as well as phase controllers. Many modern controllers meet most or every one of these minimal needs as well as a lot of controllers also provide additional functionality not yet standardized.

3 Easy Facts About Safety Network Explained

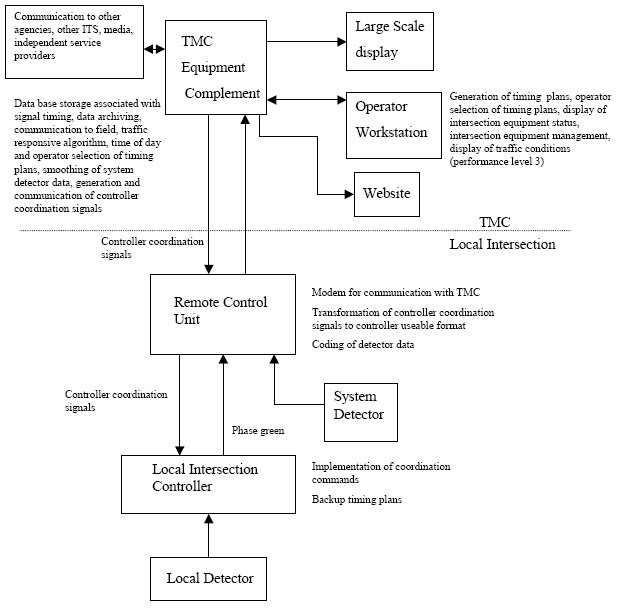

Such connections might be permanent to a remote master or computer system, or short-lived to a notebook computer utilized by field employees. Ethernet is significantly being used rather of serial communications. As special serial port might be utilized to communicate with in-cabinet tools in the situation of a serial-bus cabinet (see NEMA TS 2 and also ATC sections listed below).If a breakdown is spotted, the MMU automatically puts the signal in an all-red blinking state, overriding the results of the controller. Modern controllers can sense this problem as well as report the malfunction state to a master or main computer. Modern controllers use the following 3 different techniques of identifying which pattern or strategy to operate: Internal time-of-day routine - the user sets up a schedule that tells the controller when to transform the pattern or plan, based on the day of the week and time of the day.

If the controller loses interactions with the source of pattern commands, it can automatically return to using its interior time-of-day pattern option schedule - https://www.artstation.com/s4fetynetw0rk. The exact same interactions web link is typically used to receive status details from the controller, and also to make it possible for remote modifications to controller criteria. It is also possible for the customer to by hand lock a controller into a particular pattern, such that any of the above pattern choices is overlooked.

The Buzz on Safety Network

This is called time base control. Eventually, however, the controller's clock will wander and need to be reset to basic time. Clocks can be reset utilizing any one of the complying with techniques: Manual - occasionally, an individual mosts likely to the controller in the field as well as resets the moment according to an accurately set watch or various other resource of conventional time (e.

The Only Guide for Safety Network

This method is not favored as it is laborious, error-prone, and also subject to disregard. Relying on the design of controller, operationally considerable drift can require manual reset after just numerous weeks of procedure. Hardwire pulse - a master unit pulses a hardwire input to the controller at a pre-defined time of day.

Report this wiki page